Supporting Industries

Bringing Intelligent Insights to the Industrial Sector

Recon uses the latest surveying and scanning equipment to capture precise data and generate detailed as-built models. Whether reverse engineering complex industrial components or modelling large industrial sites, we mix traditional surveying techniques with cutting-edge technology to provide comprehensive solutions for every stage of an industrial project.

A Top-Down Approach Starting with Aerial Mapping

Aerial surveying and mapping provides a detailed and realistic, site-wide model for planning and asset management. Its fast, a large site is captured in a matter of hours and allows for data collection in hazardous and elevated areas, providing comprehensive information at any scale.

Capture can include multi-camera photogrammetry for detailed rendering, or combined LiDAR and aerial photography for survey-accurate representation of obstructed or more complex areas.

Delivery of the 3D model can include powerful visualisation tools with measuring and design functionality on your PC or cloud-based systems supporting improved collaboration across multiple project staff, management and owners.

3D Scanning & Modelling

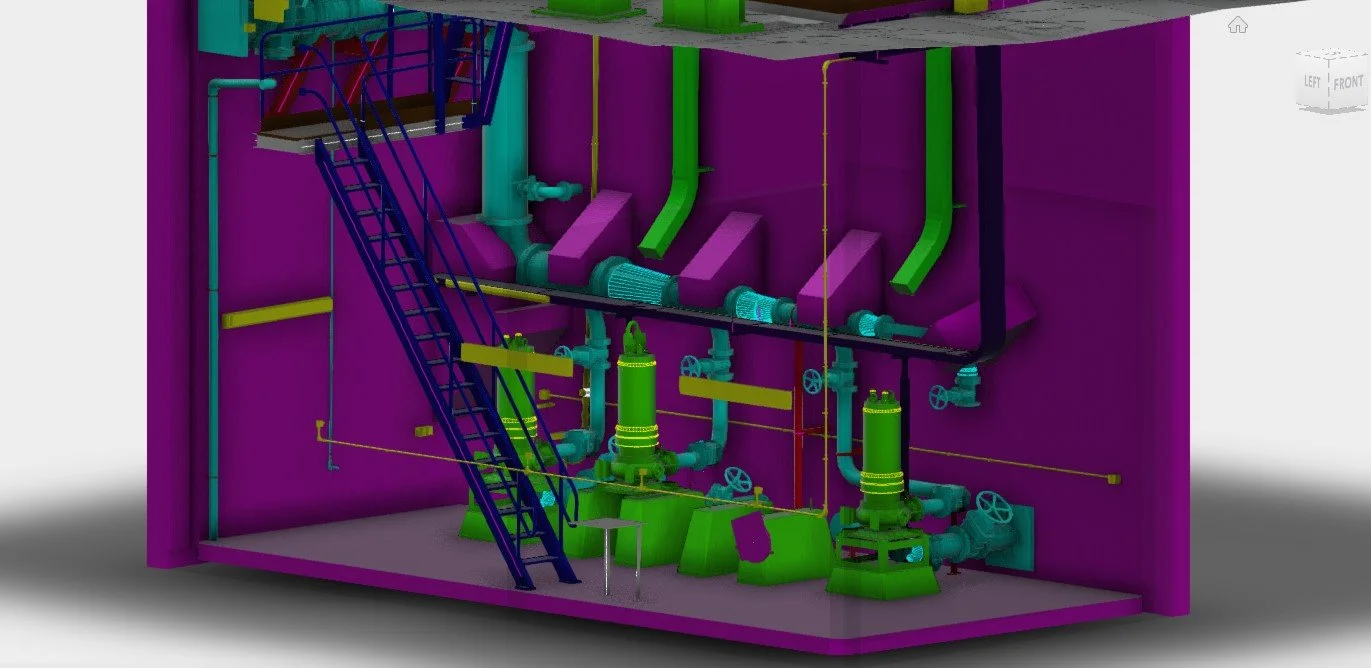

3D laser scanning is most effectively applied in industrial operations due to its speed and precision. This technology allows CAD technicians and engineers to accurately map MEP (Mechanical, Electrical, Plumbing) and structural components, helping to avoid conflicts. With its accuracy and time-saving benefits, such as enhanced safety due to capturing elevated features, 3D scanning is the most efficient and comprehensive approach for creating as-built models of these facilities.

Clash detection is particularly important, not only for placement of new equipment but understanding how it can be transported into place. This enables the project team to overcome logistical and physical challenges in the planning stage.

Laser Scanning for Overall Efficiency

Manufacturers use laser scanning services to create digital models for planning, feasibility studies, renovations and plant expansions, reducing the need for site visits. Recon’s 3D scans optimise production efficiency through desktop analysis and supporting design improvements.

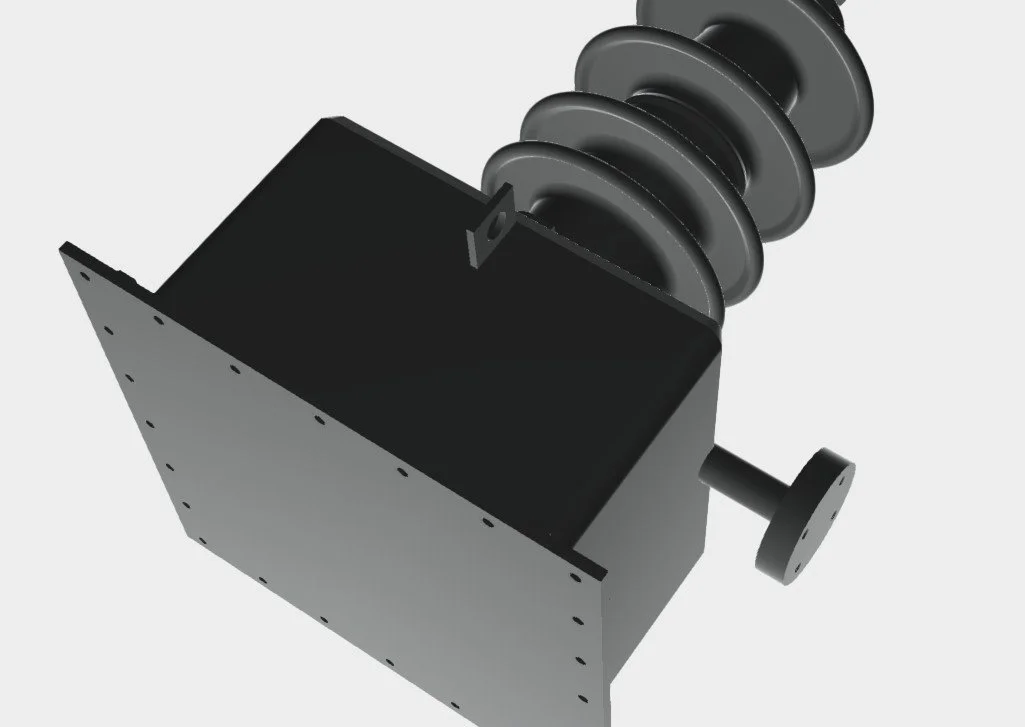

Reverse Engineering

As building usage change and technology and equipment advance, careful planning is needed to avoid delays and cost overruns. Equipment, conveyors, and components are often built off-site after the scanning, design, and drawings process is completed.

Enquiries to Recon can be made through freephone 0800 732 669 or email info@recon.nz