How advanced survey techniques helped deliver Watercare’s Interim Chemical Upgrade

Summary

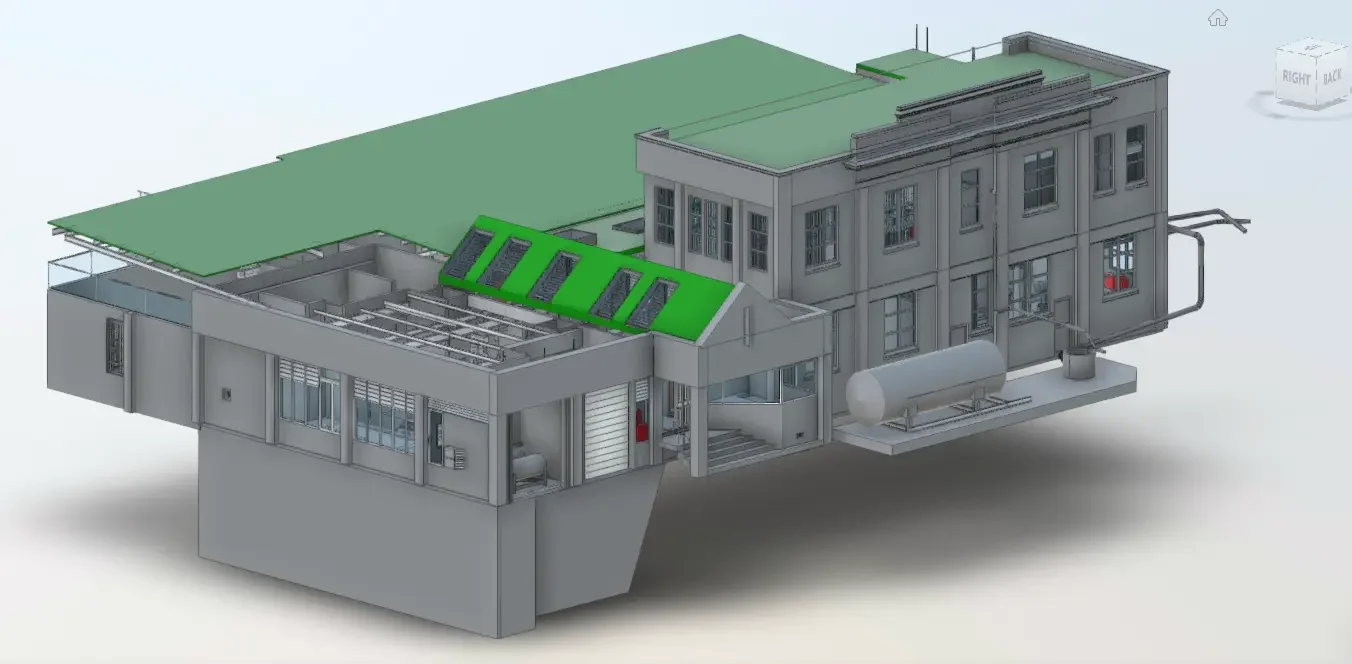

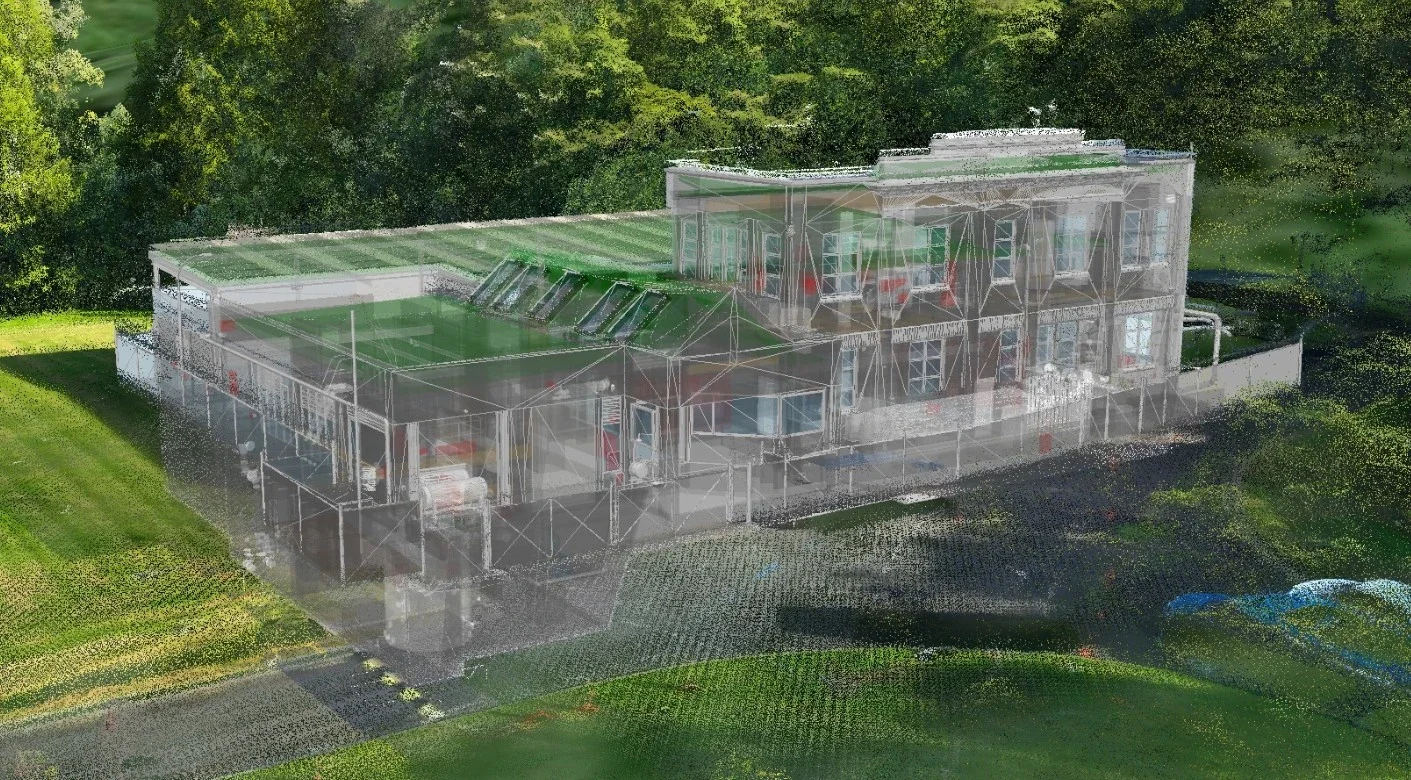

The Waitākere Water Treatment Plant is being upgraded to replace ageing, non-compliant chemical infrastructure, with PDP delivering the work. Due to known inaccuracies in legacy as-built drawings, the project used laser scanning, LiDAR, drone surveys and a Revit model to accurately capture existing conditions and support design and coordination. This digital approach reduced site visits, improved design confidence, and delivered time and cost efficiencies across the project’s multi-year, phased delivery.

Watercare’s Interim Chemical Upgrade

The treatment infrastructure at the Waitākere Water Treatment Plant is nearing 100 years old. Many of the chemical systems are outdated and no longer meet current compliance standards.

Pattle Delamore Partners (PDP) are undertaking a chemical upgrade at the treatment plant, which includes constructing new buildings for several systems and internal upgrades within the existing structures, decommissioning non-compliant assets and upgrading with new.

Watercare Survey using LiDAR, topographic survey, 3D laser scanning and REVIT modelling

At what stage of a building upgrade should we do laser scanning?

The existing as-built drawings were not referenced for this project. The team acknowledged that significant discrepancies often exist between the original drawings and the actual site conditions. Over time, new components are frequently added but not captured in the drawings. Instead, the engineers relied on new data produced by Recon including a typographic survey, 3D scanning and Revit model, drone LiDAR and aerial photography.

Lucy Douglas, Environmental Engineer at PDP explains “for the new buildings we needed topographical data to get the ground levels where we were placing buildings and what we can do around the area, because lots of the spaces were quite tight.

Inside the building, there's a lot going on and a lot of things need removing and new things going in, and its very space constrained. So having the 3D scans meant that our CAD team didn’t need to go in with tape measures! The model also highlighted areas that we might not have looked at in detail on-site, but actually it's all shown on the model”.

What are the cost/time benefits of using laser scanning instead of traditional manual survey when upgrading a building?

Sagar Makkar, Digital Design Manager at PDP adds “without the model, we would have to go to the site and measure every time if we had any questions or queries about the measurement and high points, and the locations of any services we are dealing with, so that's a huge time-saving! We have a virtual site available on our screen whenever we want, we can just visit it in a few clicks.”

What deliverables from the Revit model will support the building upgrade?

Sagar goes on to note “the 3D model we received from Recon came in very handy as we can delete or hide the existing components and apply the new assets and then create the layers, showing what’s existing and how we are planning to replace them. To be able to model an entire project on one model is super helpful. And because the model was layered, and different layers showed different elements like steel works, stairs, and tanks, it made everything easy to identify. We can then switch off different layers or hide it temporarily and add the new assets in. The model made discussions easy, as we can clearly show the client what was in the existing area and what we are planning to do.”

What file formats and software will the scan data come in, and will it integrate with our design/maintenance software?

“Getting Recon to spend the time to process the data and prepare this in a way that can best slot into our workflow and software (Revit) is really worthwhile and saves us time and cost overall. My observation is that this was done very well for this project.” Dan Garden – CPEng, Technical Director Water Infrastructure, PDP

The project is expected to span a few years due to the phased implementation of the different chemical systems.

“I think for complex Brownfield sites where there is a lot of existing stuff going on, where a topographical survey just can’t capture the information needed, then you would need the extra level of data produced, using the same techniques in this project.” said Lucy.

“I had to keep changing the date for access to the site and Jeremy was really good about it. It was never a problem for him, which was great!” said Lucy

Christopher Adonis, Senior Project Manager – Capital Delivery at Watercare said “the data provided has been very useful”.

Key Insights

Laser scanning early in design provides a reliable baseline where as-built drawings can be inaccurate.

Combining scanning, LiDAR, and drone data captures complex sites more effectively than traditional surveys.

3D models reduce repeat site visits, saving time/money.

Layered Revit models support clear planning of removals and new assets in tight spaces.

Accurate digital data improves design confidence and client communication.

Enquiries to Recon can be made through our freephone 0800 732 669 or email info@recon.nz.